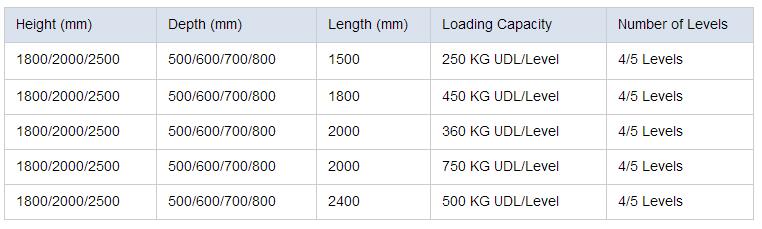

Longspan Shelving (200-800 KG UDL/Level)

IRACKING Longspan Shelving is a strong, durable, versatile and economical shelving system ideal for manual picking of products.

Features:

- Optimum solution for manually storing medium and heavy loads.

- Loading capacity 200 KG – 800 KG UDL/level as general.

- Fully adjustable shelf height by pitch 50mm.

- Easy assembly.

- A wide range of components adaptable to your specific storage needs.

Why IRACKING Longspan Shelving?

- Only high-quality RAW STEEL, by largest steel factories in China, is used for our racking products.

- With large scale production, we are in a good position to lower product costs without compromising quality.

- A wide range of different racking types are offered to suit different storage needs.

- We provide free but expert advice & proposed racking solutions for your kind reference.

- Quick delivery. Within 25 days for ordinary order quantity.

Related Products

For 100-300 Kg per level and less than 100 Kg per level loading, we also provide Medium Duty Shelving System and Light Duty Shelving System.

For palletised goods, we also provide other racking and shelving systems, including Conventional Pallet Rack, Drive-In Pallet Rack, Double Deep Pallet Rack, Radio Shuttle Pallet Rack and Very Narrow Aisle (VNA) Rack. For US market, we supply US style Teardrop Pallet Rack, also known as Rivet Pallet Rack.

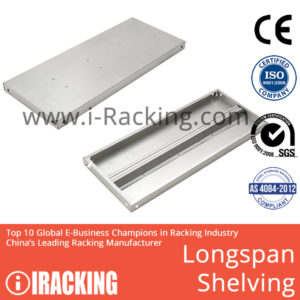

Product Details

Step beams are the horizontal components on which the load is directly deposited and on which the shelves are fitted in order to store small-sized products.

Reinforcements backside with much bigger loading capacity.

Steel Panel

Each level of longspan shelving is made up of 2 or 3 steel panels according to the beam length and the weight of the products to be stored.

IRACKING has two types of steel panels. Option 1. powder coated finish; option 2. pre-galvanized finish.

Reinforcements backside with much bigger loading capacity.

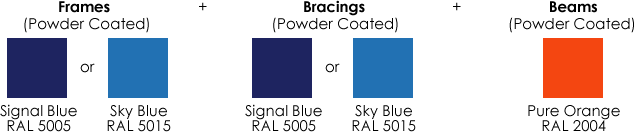

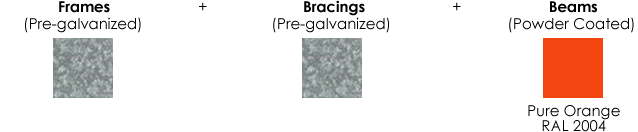

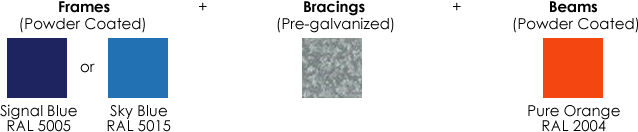

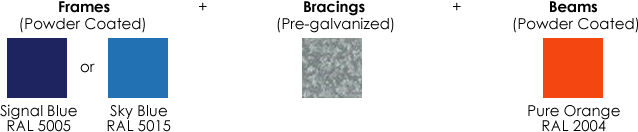

Finishes

Option 1: Frame (Powder Coated* Blue) + Beam (Powder Coated Orange) + Steel Panel (Pre-galvanized).

Option 2: Frame (Powder Coated Blue) + Beam (Powder Coated Orange) + Steel Panel (Powder Coated Light Grey) .

Option 3: Frame (Powder Coated Light Grey) + Beam (Powder Coated Light Grey) + Steel Panel (Pre-galvanized).

Option 4: Frame (Powder Coated Light Grey) + Beam (Powder Coated Light Grey) + (Powder Coated Light Grey).

* Powder epoxy-polyester coating, polymerized at 180℃, lead free.

Production Management and Services

1. Quality Management Process is standardized, quantified, and traceable. 2. Raw materials suppliers are selected prudently. Selected Q235 rolled steel strips are tested and the physical properties must meet our internal standards.

3. The raw material thickness must fall within the specified tolerance.

4. The samples of each batch of raw materials are kept for 5 years for quality traceability.

5. Each batch of raw material is tested for tensile strength, yield strength, and elongation at break. Test reports are kept in our QA system and traceable. Batch sampling rate has rosen from 50% to 100%.

6. Only experienced workers and operators are employed, followed by our internal professional training.

7. Each process of production is guided and instructed by our technical department.

8. QA is incorporated into each and every production process. Only qualified products will flow into the next process.

9. The maximum load of each type of our standardized products is tested, complemented with random sample load test for finished products.

10. Load test for non-standardized products is carried out for each batch.

We provide standard packaging and small bundle retail packaging, as requested.

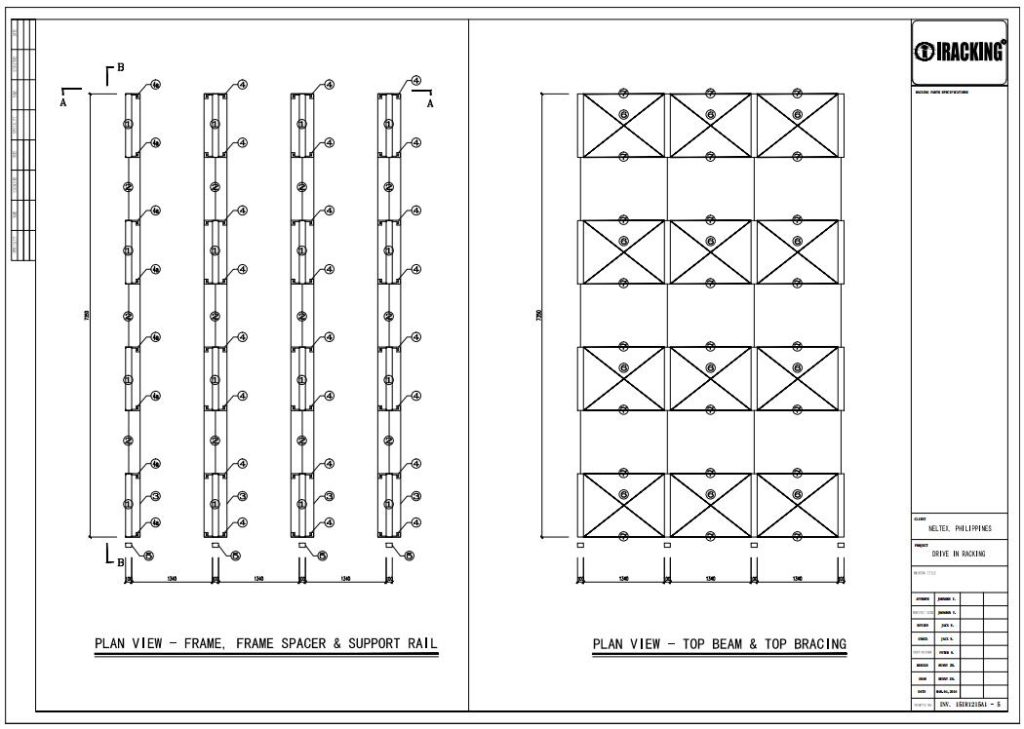

The design is an essential part of the process.

iRacking provides you a complete design matching your needs free of charge.