Pallet Shuttle Rack

Pallet Shuttle Rack System is a compact storage system in which a shuttle, driven by an electric motor runs on rails inside the storage channels, replacing forklifts, considerably reducing operating times and enabling items to be grouped by channel rather than in complete lanes.

By removing the need for forklifts to enter the lanes, storage capacity is increased in terms of depth, the risk of accidents and damage to the racks is negligible, operator movements are optimized and warehouse operation is modernized and made more flexible.

It is an ideal solution for companies with a high volume of pallets per item and intensive loading and unloading activity.

Benifits:

• Greater diversification: each channel can be used to store a different item.

• Greater diversification: each channel can be used to store a different item.

• High productivity: increased flow of incoming and outgoing goods.

• Highly cost-effective, thanks to the reduction in operating costs.

• Decreased incidents and maintenance costs.

• Cold storage. It is ideal for warehouses where low temperatures are required, since it takes full advantage of the storage volume and reduces maneuvering times.

Related Products

For different warehouse layouts and applications, we also provide similar products, including Conventional Pallet Rack, Drive-In Pallet Rack, Double Deep Pallet Rack, and Very Narrow Aisle (VNA) Rack. For US market, we supply US style Teardrop Pallet Rack, also known as Rivet Pallet Rack.

Structure of Pallet Shuttle Rack

Pallet Shuttle Rack System consists of supporting racks, shuttle rails and a shuttle cart. The shuttle cart runs on the rails and is propelled by an electric motor.

All the movements of the shuttle cart are controlled with a hand held remote control. The shuttle cart is placed in the desired lane with a forklift.

Production Management and Services

Quality Management & Control

1. Quality Management Process is standardized, quantified, and traceable.

2. Raw materials suppliers are selected prudently. Selected Q235 rolled steel strips are tested and the physical properties must meet our internal standards.

3. The raw material thickness must fall within the specified tolerance.

4. The samples of each batch of raw materials are kept for 5 years for quality traceability.

5. Each batch of raw material is tested for tensile strength, yield strength, and elongation at break. Test reports are kept in our QA system and traceable. Batch sampling rate has rosen from 50% to 100%.

6. Only experienced workers and operators are employed, followed by our internal professional training.

7. Each process of production is guided and instructed by our technical department.

8. QA is incorporated into each and every production process. Only qualified products will flow into the next process.

9. The maximum load of each type of our standardized products is tested, complemented with random sample load test for finished products.

10. Load test for non-standardized products is carried out for each batch.

We provide standard packaging and small bundle retail packaging, as requested.

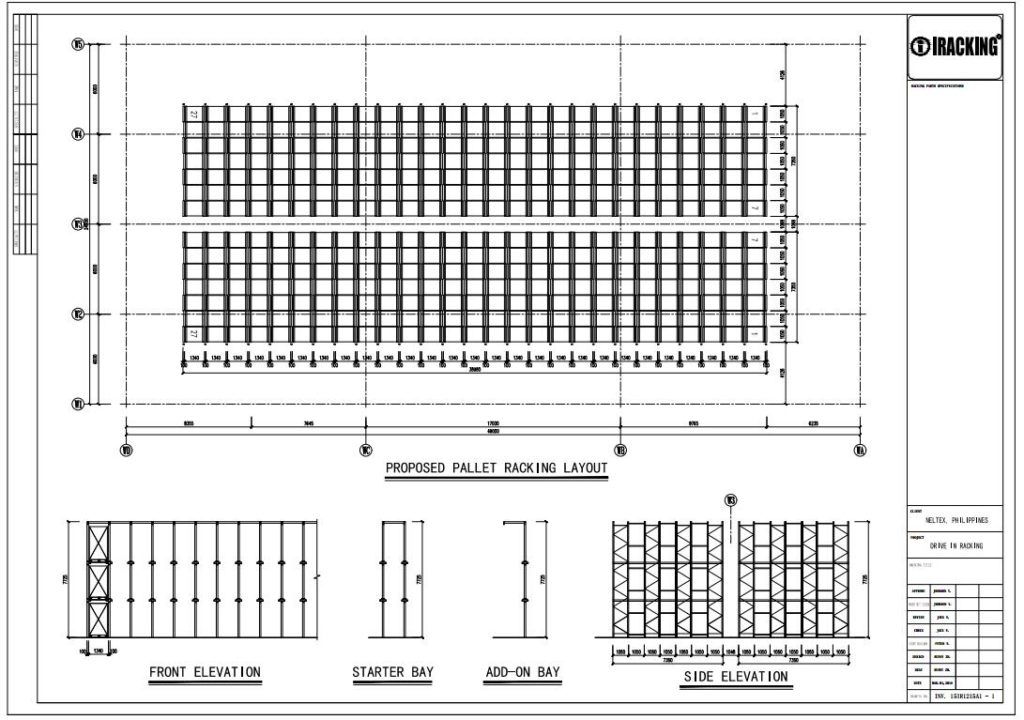

The design is an essential part of the process.

iRacking provides you a complete design matching your needs free of charge.