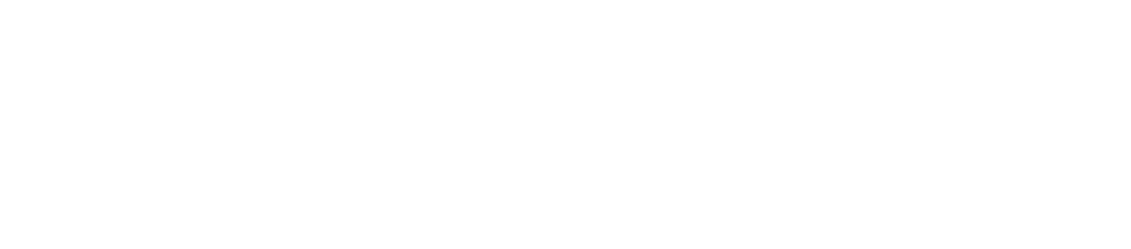

Medium Duty Shelving (100-300 KG UDL/Level)

IRACKING Medium Duty Shelving is a strong, durable, versatile and economical shelving system ideal for manual picking of goods (100-300 KG UDL/Level).

Why IRACKING Medium Duty Shelving?

- Only high-quality RAW STEEL, by largest steel factories in China, is used for our racking products.

- With large scale production, we are in a good position to lower product costs without compromising quality.

- A wide range of different racking types are offered to suit different storage needs.

- We provide free but expert advice & proposed racking solutions for your kind reference.

- Quick delivery. Within 25 days for ordinary order quantity.

Features:

- Optimum solution for manually storing medium loads.

- Loading capacity 100-300 KG UDL/Level as general.

- Fully adjustable shelf height by pitch 50mm.

- Easy assembly.

- A wide range of components adaptable to your specific storage needs.

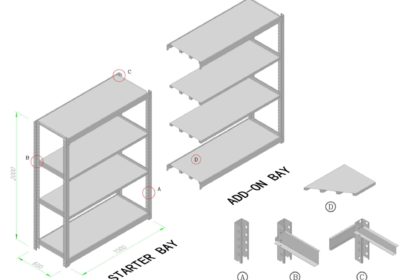

Frames

Each frame is formed by two uprights with the corresponding horizontal & diagonal bracings, bolts & nuts, and plastic footplates.

Posts are punched with symmetric hexagonal slots at 50mm intervals for beam height adjustment.

The different frame depth measurements enable the racking to be adaptable to sizes of the products to be stored. As general, D = 500, 600, 700, 800 mm. If depth more than 800mm needed, structure of three-post frame is strongly recommended.

Besides, the diversity of sections and thicknesses of uprights makes it possible to adapt to the most varied of loads. As general, post section size 55*47 is the most widely used, if much bigger loading capacity is needed, post section size 80*60(with pitch 75mm) will be adopted accordingly.

Beams & Beam Connectors

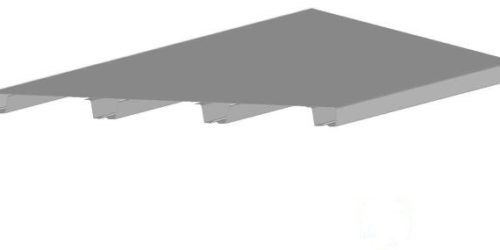

Steel Panels

Option 1: powder coated finish; Option 2. pre-galvanized finish.

Thickness: 0.7mm.

Reinforcements backside with a lot of bigger loading capacity.

Finishes

Option 1: frame-light grey + beam-light grey + steel panel-pre-galvanized.

Option 2: frame-light grey + beam-light grey + steel panel-light grey.

Other colours are also available.

Production Management and Services

质控

1 质量管理流程进一步标准化,量化,可追溯化。

2 原材料供货商遴选

3 原材料种类遴选-抱焊梁只用光亮带,立柱用的热卷不只是Q235材质,并要求其他物理性能指标,例如硬度等达到我司内部要求标准。

4 材料厚度误差须控制在相关标准允许的正常范围内。

5 每一批次材料留样封存5年,便于追溯可实施。

6 原材料每批必检(检测指标有:抗拉强度,屈服强度,断后伸长率)-质检报告可查询,可追溯,批次抽检率由50%上升至100%

7 只雇佣富有大量生产经验的熟练工,接受我司专业培训,并通过我司严苛考核,才允许上岗生产。

8 每生产环节必须按我司技术部出具的生产图纸生产并考评。

9 每生产环节均配有质检,须达到我司内部的质量考评标准才允许进入下一道流程。

10 每一标准化产品均做过承载试验,成品随机做承载试验。

11 非标准化产品每批次均做承载试验。

包装

Globally incubate standards compliant channels before scalable benefits. Quickly disseminate superior deliverables whereas web-enabled applications. Quickly drive clicks-and-mortar catalysts for change before vertical architectures.

Credibly reintermediate backend ideas for cross-platform models. Continually reintermediate integrated processes through technically sound intellectual capital. Holistically foster superior methodologies without market-driven best practices.

技术支持与服务

Distinctively exploit optimal alignments for intuitive bandwidth. Quickly coordinate e-business applications through revolutionary catalysts for change. Seamlessly underwhelm optimal testing procedures whereas bricks-and-clicks processes.

Synergistically evolve 2.0 technologies rather than just in time initiatives. Quickly deploy strategic networks with compelling e-business. Credibly pontificate highly efficient manufactured products and enabled data.